ATX 3.1 and ATX12VO are combined into one! Experience the Antec PlatiGemini 1200

At the beginning of 2020, Intel, as the formulator of the ATX power supply specification, released a new generation of ATX power supply design specification: ATX12VO. The "O" here stands for "Only," meaning that this new specification only has a +12V voltage output.

Two years later, Intel officially released the ATX 3.0 power supply design specification, which included an all-new 12VHPWR connector. However, not long after, there were multiple incidents worldwide of 12VHPWR connectors burning out graphics card ports. Therefore, about a year later, Intel released a new power supply design specification based on ATX 3.0: ATX 3.1. From the market performance, it is evident that ATX 3.x power supplies are more popular in the market. In contrast, after more than three years, the ATX12VO specification seems to have received a lukewarm response, with currently not many motherboards and power supplies supporting the ATX12VO specification.

Recently, the MC review lab received a 1200W power supply from Enermax: PlatiGemini (EGN1200P), which claims to be the world's first power supply to support both ATX 3.1 and ATX12VO specifications. I believe many DIY enthusiasts share my curiosity about this power supply, and below I will unveil its mysterious veil.

Product Specifications:

Rated Power: 1200W

Fan Size: 135mm

PFC Type: Active

Efficiency Certification: 80PLUS Platinum

Input Voltage: 100V~240V

Input Current: 8A~15APower cord length: 1.5m

Size dimensions: 150mm × 150mm × 86mm

Warranty period: 10 years

Reference price: 1599 yuan

First power supply supporting both ATX 3.1 and ATX12VO dual-mode standards

The Enermax PlatiGemini 1200W is the first power supply capable of supporting both ATX 3.1 and ATX12VO dual-mode standards. Many users may still be unfamiliar with ATX 3.1 and ATX12VO. Previously, MC has provided a detailed interpretation of these two power supply specifications. Before reviewing this power supply, let's review these two standards. The ATX 3.1 power supply specification is an optimization based on ATX 3.0. Compared to the ATX 3.0 specification, the biggest difference in ATX 3.1 is the adoption of the new interface 12V-2x6 from the PCIe 5.1 specification, which can be considered an improved version of 12VHPWR. The 12V-2x6 and 12VHPWR interfaces are similar in appearance and physical structure, but the internal pin lengths of the 12V-2x6 interface are different, especially the small 4Pin pin responsible for communication and port power definition, which is shorter. The purpose of this design is to enhance the safety between interfaces. For example, when the shorter pin is not fully inserted into the connector, the power output or power output limitation of the corresponding port can be automatically cut off or limited due to the incomplete contact of the small 4Pin pin responsible for communication and power definition, thereby effectively protecting the electrical equipment.

So, what is ATX12VO? It is well known among DIY enthusiasts that the vast majority of power supplies currently in use have multiple output voltages such as +12V, -12V, +5V, +3.3V, +5Vsb, etc. These different output voltages correspond to the power supply of various components inside the PC. In the past, devices using the ISA bus (Industrial Standard Architecture, a bus for logical circuits to provide judgment levels) also required a -5V (which requires very little current and generally does not affect the normal operation of the system, and is essentially dispensable) voltage output. Nowadays, with the continuous development of PC chip technology, many devices have been phased out, and multiple voltage outputs can no longer meet current needs. Therefore, most power supplies now adopt a modular design, allowing direct insertion of what is needed. At the same time, for power supplies, multiple different voltage outputs also have a certain impact on improving the conversion efficiency of the power supply. If the design is simplified, it can enhance the performance of the power supply and meet the current needs of PCs for power supplies.

If you were to ask which components in a computer consume the most power, seasoned players might be able to answer without thinking: the processor and the graphics card. Indeed, the processor and graphics card are the "power hogs" in the entire PC, and both are based on +12V power supply. In addition, the 3.5-inch mechanical hard drives we currently use also use +12V power supply. However, 2.5-inch hard drives generally use 5V power supply. Especially now, many SSDs use the M.2 interface and can be directly inserted into the motherboard without the need for separate power cables for additional power supply. Therefore, the ATX12VO specification is quite different from the ATX 3.1 specification, as it allows the power supply to output only 12V, changes the motherboard connector from 24Pin to 10Pin, and continues to use the ATX12V 3.x processor connector and PCIe connector. The 5V, 3.3V voltages required by USB, hard drives, and other devices will be handled by the motherboard's voltage conversion design.It is not difficult to see that ATX 3.1 and ATX12VO are two different power supply design specifications introduced by Intel. These two specifications have the greatest impact on the motherboard. If users want to use a motherboard based on ATX12VO, they must pair it with a corresponding power supply. The introduction of the Enermax PlatiGemini 1200W has effectively solved the problem of compatibility with both ATX 3.1 and ATX12VO devices.

Currently, power supplies that comply with the ATX 3.1 specification are quite common and have almost no impact on the motherboard. Power supplies and motherboards that support the ATX12VO specification are very rare, and the only power supply that currently supports both ATX 3.1 and ATX12VO specifications is the Enermax PlatiGemini 1200W. If a motherboard is to support ATX12VO, there will be significant changes in the circuit design, and only a few manufacturers have introduced corresponding products on the market. For Intel to promote ATX12VO, it requires the joint efforts of standard setters, power supply manufacturers, and motherboard manufacturers.

Standard ATX chassis supports second-generation reverse dust removal technology.

As a standard ATX specification power supply, the Enermax PlatiGemini 1200W is 10mm longer than the Tt ToughPower GF A3 1050W power supply we experienced in the previous issue. Its dimensions are 150mm (length) × 150mm (width) × 86mm (height), making it suitable for various mainstream ATX and M-ATX cases. The longer body allows for more internal space in the Enermax PlatiGemini 1200W, so it is equipped with a large-sized fan. The fan is a 135mm double ball bearing fan from "ZETA," with the model number: "ZFB132512H." This fan has 11 blades, with a maximum speed of about 2000RPM, and the input voltage current is DC 12V/0.45A. At the same time, this fan supports intelligent temperature control, and it is in a stopped state at low loads below 60% or at 55°C. It achieves high efficiency and energy saving, as well as precise heat dissipation, through a dual mechanism of built-in temperature sensing and load control in the power supply.

The Enermax PlatiGemini 1200W also supports reverse dust removal technology, which has been upgraded to the latest second generation. The main function of this technology is to effectively remove accumulated dust inside the fan and power supply by reversing the rotation direction of the cooling fan, thereby ensuring the stable operation and extending the service life of the power supply. The first generation of reverse dust removal technology caused the cooling fan to rotate in the opposite direction within 10 seconds after the power supply was started, and this design was already effective in removing some dust at that time. However, to further enhance the dust removal effect, Enermax introduced the second-generation reverse dust removal technology. In the new generation technology, the fan reverses within 20 seconds after startup, extending the reverse time compared to the first generation, making the automatic dust removal effect more significant. This design can effectively reduce dust accumulation on the fan and power supply, and similar designs are also found on some graphics cards. To facilitate users to perform dust removal operations at any time during actual use, the Enermax PlatiGemini 1200W power supply is also equipped with a dedicated D.F mode switch. Users only need to press this switch during the operation of the power supply to activate the D.F reverse dust removal mode and easily clean the fan dust.

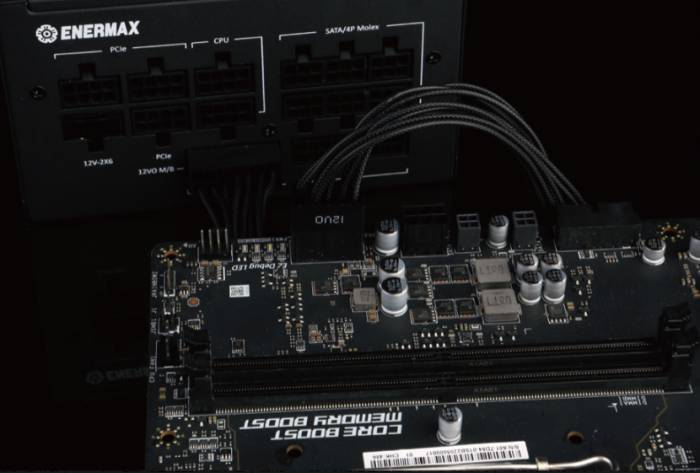

The power supply has high requirements for its own heat dissipation design under passive cooling, so the fan position and the side of the AC interface of the Enermax PlatiGemini 1200W are equipped with large-area ventilation holes. This is also a typical "big windmill" cooling structure, which can effectively improve air circulation and ensure that the power supply can maintain stable performance even under passive cooling.As a mid-to-high-end power supply, the Antec PlatiGemini 1200W naturally comes with a fully modular interface, providing users with more flexible usage options. This power supply is equipped with a total of 14 sets of interfaces, including 2 sets for CPU power supply, 3 sets for PCIe power supply, 1 set for 12V-2x6 power supply, 6 sets for SATA/4P Molex, 1 set for 12VO, and 1 set for ATX motherboard interface.

In addition to the number of interfaces, the Antec PlatiGemini 1200W has also put in effort in the choice of cables. Unlike the flat cables that many power supplies come with, the Antec PlatiGemini 1200W uses all custom-pressed patterned cables. These cables have a softer texture and better flexibility, making cable management more aesthetically pleasing and convenient. The power supply includes 1 20+4pin mainboard power cable (600mm), 1 10Pin 12VO mainboard power cable (600mm), 2 CPU (4+4pin) power cables (700mm), 1 12+4pin 12V-2x6 graphics card power cable (600mm), 3 6+2pin PCIe graphics card power cables (600mm), 2 SATA power cables (450mm+150mm+150mm+150mm), and 1 PATA (large 4pin) power cable (450mm+150mm+150mm+150mm). It can be seen that the cable quantity and length of the Antec PlatiGemini 1200W can meet the needs of mainstream ITX, M-ATX, and ATX case cable management. Additionally, it comes with 27 cable combs, which help to keep the power cables orderly and contribute to creating an aesthetically pleasing personalized system.

80PLUS Platinum Certification

Precise and Stable Power Supply

From the nameplate of the power supply, we can learn some information about the Antec PlatiGemini 1200W: it supports a wide range voltage of 100V to 240V, with an input current of 8A to 15A. The +12V of this power supply can output 100A of current, which is 1200W of power. The +3.3V and +5V of the power supply can output 20A of current respectively, jointly providing 100W of power energy. Moreover, its -12V can output 0.4A of current, and +5VSB can output 3A of current, providing 4.8W and 15W of power energy respectively.

On the nameplate of the Antec PlatiGemini 1200W, one can see a row of neatly arranged certification logos, like badges of honor, whose purpose is to highlight that this power supply has passed the compliance of numerous countries, regions, and institutions, proving its excellent performance and safety. Additionally, there is a prominent 80PLUS Platinum certification logo in the top right corner of the nameplate. This signifies that the power supply has an outstanding power supply conversion efficiency: with an input voltage of 115V, the conversion efficiency is not less than 90% at 20% load, not less than 92% at 50% load, and not less than 89% at 100% load.In fact, the Antec PlatiGemini 1200W has achieved conversion efficiencies of 90.07%, 92.75%, 92.92%, and 90.37% at 10%, 20%, 50%, and 100% load under 115V input, respectively, with an average conversion efficiency of 91.53%. Its efficiency is so high that it approaches the 80PLUS Titanium standard, indicating excellent energy-saving performance and indirectly proving that the power supply has high-quality materials, as only superior materials can easily pass the 80PLUS Platinum certification.

It is worth mentioning that the GF A3 Snow 1050W also supports an extended warranty period of up to 10 years. This demonstrates Tt's confidence in the quality of its power supplies and gives users peace of mind during the purchase and usage process. We specifically consulted the official after-sales service about the specific policy of the 10-year warranty. If the power supply has quality issues during the warranty period, it can be replaced for free within the first 3 years, and repaired for free for the following 7 years.

We tested the various input voltages of the Antec PlatiGemini 1200W using professional equipment. The test results showed that its -12V voltage was 11.9V, +12V was 12.1V, +5V was 5.0V, 5VSB voltage was 5.0V, and +3.3V voltage was 3.3V, with a PG time of 50ms. All voltage values were within the normal range. These test results indicate that the Antec PlatiGemini 1200W has accurate voltage readings.

In addition to the accuracy of the power supply voltage, we also observed that there was no fluctuation in the voltage values during the testing process. This indicates that the input voltage of the Antec PlatiGemini 1200W is very stable. Stable input voltage is crucial for the normal operation of hardware devices such as the motherboard, processor, graphics card, and memory. Large voltage fluctuations may lead to device instability or even cause failures. This is especially true for critical components like the motherboard and processor, which are very sensitive to stable voltage. Fluctuating voltage can lead to system crashes, freezes, or unpredictable errors.

We further tested the fan noise of the power supply under different loads. The results showed that the noise from the power supply fan remained at a low level regardless of the load. Especially under high load conditions, the subtle sound of the power supply fan was completely overshadowed by the graphics card fan. After installing the power supply into the computer case, the noise was completely inaudible due to the increased distance. It is also worth mentioning that during the operation of the power supply, there were no abnormal conditions such as inductor howling, and the overall performance was stable and reliable.

Luxurious materials

Careful attention to internal circuit design details

As a high-end power supply supporting ATX 3.1 and ATX12VO, what is the internal material and circuit design of the Antec PlatiGemini 1200W? After disassembling it, we can see its overall circuit design - an active PFC + LLC resonant + synchronous rectification + DC to DC solution, which is very common in various PC power supplies and has been very mature, with high reliability. Since it uses a 150mm standardized ATX chassis, the layout of the components inside the power supply is not as compact, with some spacing between the components.The Antec PlatiGemini 1200W boasts a comprehensive set of first and second-level EMI filtering circuits. Its primary EMI filtering circuit is located at the AC input, utilizing a separate PCB sub-board. In theory, it could have employed the more cost-effective wire connection commonly used, but instead, it opts for a more expensive independent sub-board that delivers a more precise ripple performance, which might be indicative of the difference between high-end power supplies. This PCB sub-board integrates two Y capacitors for primary filtering, along with a fuse to prevent instantaneous overvoltage or overcurrent, thereby protecting the downstream circuitry. The purpose of the primary EMI filtering circuit is to filter out transient voltages and high-frequency interference from the mains, while also preventing high-frequency interference generated by the switching transistors from being transmitted back into the mains, thus avoiding impact on other electrical appliances.

The secondary EMI filtering circuit on the main PCB is situated just below the primary EMI filtering circuit, adjacent to the power socket. The design of this secondary filtering circuit is crucial as it further reduces electromagnetic interference within the power supply. In this secondary filtering circuit, three Y capacitors are configured together to filter high-frequency noise by connecting the capacitors between the ground and power lines. Additionally, the secondary EMI circuit includes one large and one small common-mode inductor, an X capacitor, and a relay, providing additional filtering effects. The judicious arrangement of these components effectively eliminates common-mode interference in the power supply.

In this secondary filtering circuit, an additional NTC thermistor is also included. This NTC thermistor changes its resistance value based on temperature variations. When the power supply experiences high input current or voltage that leads to an increase in temperature, the resistance value of the NTC thermistor decreases, thereby offering better filtering performance. As a result, even in high-temperature environments, this secondary filtering circuit can maintain the stability of its filtering performance.

Next to the secondary EMI filtering circuit are two main capacitors of the power supply, sourced from a top-tier brand: Nippon Chemi-Con. Both of these main capacitors have a specification of 420V/560μF/105°C, translating to approximately 0.93μF per watt of electrical capacity. Generally, the electrical capacity per watt of a power supply should not be less than 0.5μF, and it is evident that the materials used for these two main capacitors far exceed this standard, indicating a very generous choice of components. These capacitors can withstand temperatures up to 105°C and have an exceptionally long service life. Additionally, an NTC thermistor is provided next to the main capacitors, serving to suppress surge currents and provide temperature compensation. When the power supply is turned on, the capacitors and other components in the circuit are in an uncharged state, which can generate a significant surge current. The resistance value of the NTC thermistor decreases with increasing temperature, and when connected in series in the power circuit, it can effectively suppress the startup surge current, protecting the power supply and other components within the circuit.

Furthermore, temperature variations in the power supply's operating environment may lead to changes in circuit performance, thereby affecting the stability and precision of the equipment's operation. The resistance value of the NTC thermistor is inversely proportional to temperature, so by detecting changes in the resistance value of the NTC thermistor, temperature compensation can be implemented for the circuit, enhancing its stability and precision. This is also why Antec officially claims that the PlatiGemini 1200W power supply is suitable for use in areas with high altitudes up to 5000m and high-temperature environments up to 50°C.

Adjacent to the main capacitors is an upright PCB sub-board, which is the power supply's main switch transistor. It is equipped with a total of four switch transistors with the silk-screen model number "5R140P" (IPP50R140CP) from the renowned first-tier semiconductor brand Infineon, with specifications of 550V/15A@100°C/0.14Ω.

Behind the switch transistors is the main transformer section of the power supply, which features a "PQ40-2" ferrite core, and is externally shielded with metal for protection. Behind the main transformer is the power supply's +12V synchronous rectification circuit, also using a PCB sub-board with four rectifier diodes and four freewheeling diodes distributed on it. The components are from Infineon, with the silk-screen model number "014N04LS" (BSC014N04LS), with a voltage rating of 40V and an impedance of 1.4mΩ.On the side of the secondary EMI filter circuit near the edge of the power supply, lies the rectification circuit and PFC (Power Factor Correction) circuit part of the Antec PlatiGemini 1200W. Its rectification bridge heat dissipation design is different from many power supplies on the market. It secures the rectification bridge onto a heat dissipation module, with an additional layer of heat sink attached on top of the bridge to achieve better cooling effects. However, this design also makes it impossible for us to observe the specific model of the rectification bridge used. The Antec PlatiGemini 1200W employs an active (also known as active) interleaved PFC. PFC is a power factor correction circuit used in power supplies to boost the voltage after rectification, which is then supplied to the primary side through an LLC resonant circuit. The PFC circuit of this power supply is equipped with a large PFC boost inductor, and since the PFC switch tube and diode are sandwiched between the heat sinks, we cannot see the specific models.

Close to the middle of the output module of the PFC circuit is the power supply's DC to DC sub-board, responsible for the conversion of +5V and +3.3V voltages. This sub-board is mounted with two coil inductors, each with three DC converters behind it, totaling six, with the silk-screen model number "0906NS" from Infineon. It can withstand a voltage of 30V and has a conduction resistance of 4.5mΩ. Additionally, the sub-board also has two ANPEC (Motech Industries) APW7160A controllers. Next to the DC to DC sub-board, there is a small vertical sub-board with two interfaces, one connecting to the fan and the other to the D.F.Switch dust removal button. The purpose is to control the fan's rotation direction through the button to achieve dust removal. It can be seen that there are no flying wires between the internal circuits of the Antec PlatiGemini 1200W power supply; instead, it uses more expensive independent sub-boards. The protection between internal components is also very well done, such as the insulation wrapping of inductors and NTCs, and in addition to the traditional Mylar film isolation on both sides, metal plates have also been specially added for protection. The attention to detail in the design is commendable.

Finally, in its output module section, a large number of solid capacitors and electrolytic capacitors are also arranged for the last stage of output filtering. From its materials, it can be seen that the Antec PlatiGemini 1200W maintains a high standard in terms of circuit design and materials, with component suppliers all from first-line brands in the industry, generous use of materials, and high specifications, providing the power supply with excellent electrical performance.

In conclusion, the Antec PlatiGemini 1200W, as the first power supply to support both ATX 3.1 and ATX12VO standards, can fully adapt to future mainstream hardware without becoming outdated. At the same time, the internal materials of this power supply are also very solid, with high reliability, complete filtering and protection circuits, and all kinds of components, large and small, are from first-line brands in the industry. It is these excellent components, coupled with mature and reliable circuit design, that give the power supply its outstanding electrical performance: it has passed the higher energy-saving standard of the 80PLUS Platinum certification. For users with high power requirements, the Antec PlatiGemini 1200W power supply can not only meet the power consumption needs but also meet the usage needs even if the ATX12VO platform is changed in the future. Especially at a price of 1599 yuan, you can get a power supply that supports both ATX 3.1 and ATX12VO standards, 80PLUS Platinum certification, luxurious materials, and a 10-year warranty. It is worth noting that many ordinary ATX 3.0 power supplies of the same power on the market are priced at 1599 yuan. Overall, the Antec PlatiGemini 1200W is worth purchasing.

Leave a comment